In addition to the graphical information expressed in Drawings, the engineer has to provide various specifications (BOM) to ensure the production process. They contain information on parts, workpieces, total quantity of materials, etc. Wood products have their own unique specifications in terms of the information provided. One of the most important features of our Extensions is the automated generation of reports containing all the information needed to start production of the designed product. The BOM generator (BOMapp) reads this information from the model, processes it flexibly and presents it in the required form within the company. This function is implemented by the BOM (Bill Of Material) team. The report generator presents its information in a variety of text documents, one of the most popular being MS Excel.

For the BOM generator to function, a spreadsheet editor should be installed on the computer (to configure and open BOM templates if necessary). One of the most commonly used spreadsheet tools is MS Excel. However, if the user has a JoinerCAD or Standalone license, then they can also use the Google Sheets functionality, which allows them to upload templates to cloud storage and edit them.

The BOM generator allows you to flexibly organise the output data into different forms, which are described in Templates. The templates we provide are MS Excel files containing the keywords that are used to build the final report tables. The user can easily and simply modify these templates and adapt the information generated to their needs.

The Woodwork for Inventor installation file contains BOM templates. They are available on:

▪C:\Users\Public\Documents\Woodwork for Inventor\BOM Templates

The JoinerCAD and Standalone installation files contain BOM templates. They are available on:

▪Windows OS - C:\Users\Public\Documents\WW Data\BOM Templates

▪macOS - /Users/Shared/WW Data/BOM Templates/

If a user is logged into the BOMapp environment, they can see the same templates uploaded to our cloud storage. The templates in this storage are always updated.

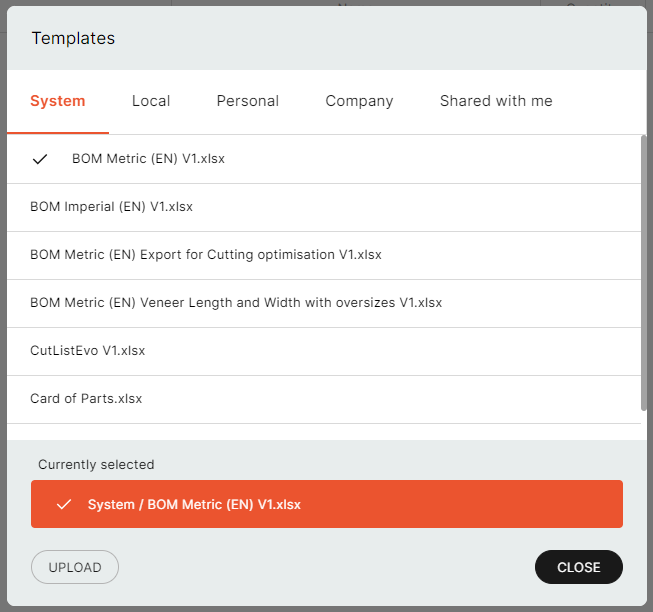

BOMapp system templates

Some of the templates we provide are:

▪BOM Metric (EN).xlsx - BOM template in metric (English).

▪BOM Imperial (EN).xlsx - BOM template in imperial (English).

These templates contain the following sheets:

▪Product Structure – BOM of the product structure.

▪Composite Parts List – BOM of composite parts with a breakdown of internal structure.

▪Multilayer Parts List – BOM of parts from a Multilayer board.

▪Complete Parts List – complete parts list for all types of materials.

▪Cutting Parts List – list of parts to be cut.

▪Material Summary – summary of materials.

▪Structured Material Summary – structured summary of materials.

▪Material Sum by Products – summaries of materials by products inside a product.

▪Rename Configuration – the Rename Configuration provides a list of materials that specifies which material names have come from the extension database. In the case of Woodwork for Inventor, if we are talking about purchased components, the names read from the iProperties component have been changed to other names during the configuration of the changes.

These templates can be used as prototypes and can be modified at your discretion to suit your business needs.

In addition, here are some templates illustrating other features of BOM generation:

1.BOM Metric (EN) Export for Cutting optimisation.xls is a BOM template that creates a BOM suitable for importing into Shape nesting applications.

2.BOM Metric (EN) Export to ERP by Part Name.xls – BOM template that creates a full hierarchy BOM showing the relationship between components. When read by a machine, it can be used to reconstruct the structure. The relationship is described by two columns: the ID of the item itself and the ID of its parent item. The component field “Code”, which is taken from the 3D model data tree, serves as the ID.

3.BOM Metric (EN) Export to ERP by Unic number.xls – BOM template that creates a full hierarchy BOM showing the relationship between components. When read by a machine, it can be used to reconstruct the structure. The relationship is described by two columns: the ID of the item itself and the ID of its parent item. The component’s internal BOM numbering field “Number”, which is taken from the 3D model data tree, serves as the ID.

4.Simple Cutting List with Underscores Metric (EN).xls – BOM template where the length and width of the workpiece are underlined respectively with the Edge band.

5.Price calculation (EN).xls – BOM template that automatically calculates material prices. This template requires a Price list.xls file, which is provided alongside the BOM template.

The following sections describe the rules to follow to describe a BOM template and how to operate the BOM generator.

More information is available in the following sections:

▪Work and navigation in the BOM generator's window