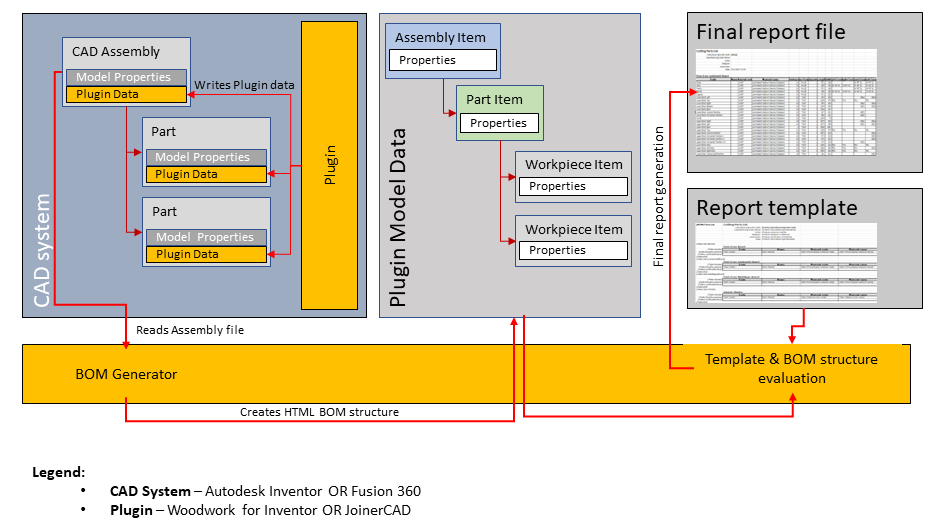

The extension provides the functionality that allows CAD system components to be assigned additional data specific to wood products. Characteristics such as Grain direction, Edge band assignment, material type, etc. can be mentioned. All this data, together with the geometry of the components, is then interpreted by the BOM generator and brought together in a hierarchical tree-like data structure. This can be called Model Data.

The model data can be written to a file with the extension *.wbom. These files contain all the information about the product, with each component having an information container about itself. You can see this information in the BOM generator (BOMapp) window. This not only contains the component code and name, which come from the CAD system’s component properties (e.g. iProperties), but also the wood product-specific data that are interpreted and displayed by the BOM generator. These are the various dimensions of the part, the list of blanks that make up the part. Also the dimensions of the parts, the materials used to make them, etc.

The BOM generator does not process those components that do not have a CAD material assigned by the extension.

If the Woodwork for Inventor extension is used and the document does not have a document type set to “Normal” or “Purchased”, it will not be accounted for. Documents of type “Purchased” are entered in the model data as purchased products. Also, the BOM generator excludes those instances of the Assembly Occurrences for which the instance type is set to “Referenced”.

If using the JoinerCAD extension, the BOM generator will only process those components that: (A) have a set type “Normal” and an assigned material group; (B) have a set status “Qualitative”, which allows components to be treated as purchased and counted in units; (C) or, if the component has a status “Translucent”, it is rendered transparent in the system and ignored.

The BOM generator can read *.wbom files repeatedly without relying on CAD data. It is also possible to open several such files in the generator and merge them into a single BOM. This allows you to change the quantities of products to be included. As a result, it is possible to organise a joint specification for a production order without having to create it as an assembly model in the CAD environment. In addition, the BOM generator can process and manipulate the data using an application programming environment (API).

The Workflow requires specifications in various forms to ensure the seamless flow of the business process. The BOM generator can therefore output the information to an easy-to-read and use MS Excel file or most other text file formats (.txt, .ods, .xml etc.). From now on, we will refer to this output information as the the Bill Of Materials (BOM).

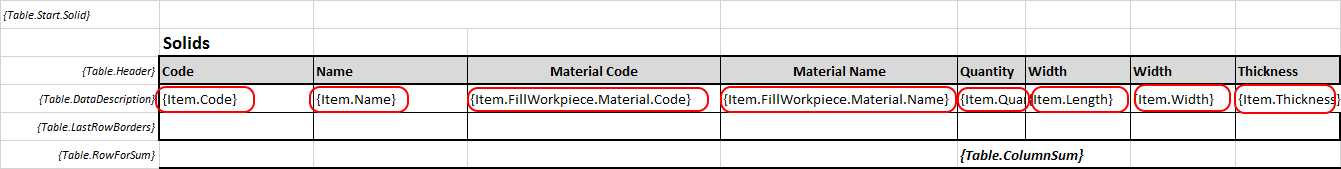

BOM template example

To accommodate the variety of reporting formats, it is foreseen that the user can describe a template for the reporting format (see figure below). In this example, the template is created as an MS Excel file. In this file, the desired columns contain the keywords interpreted by the BOM generator. The generator sequentially reads the items in the model data and, cell by cell, according to the keywords set out in the BOM template, finds the data requested by the keyword and writes it into the corresponding column of the table. In this way, item by item, their information is laid out in rows in the reporting tables. This way of creating BOMs allows a wide range of templates to be created, without programming skills, to meet the diverse workflow needs of the furniture manufacturing business

Principal scheme of BOM Generator

With our CAD extensions, sample BOM templates are included in the installation.

They are available in three places:

▪For Woodwork for Inventor:

C:\Users\Public\Documents\Woodwork for Inventor\BOM Templates (local)

▪For JoinerCAD and Standalone:

windowsOS - C:\Users\Public\Documents\WW Data\BOM templates (local)

macOS - /Users/Shared/WW Data/BOM Templates/

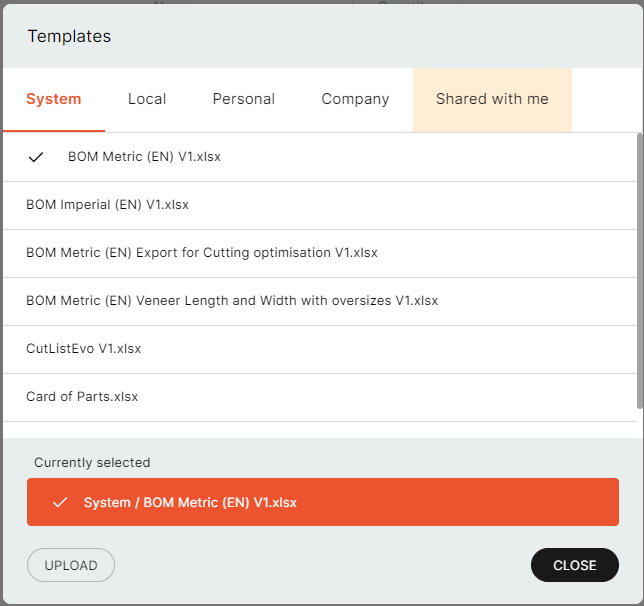

▪Alternatively, you can download and use the always up-to-date templates directly from the BOMapp environment.

Select WEB Template

Important!

They can be modified and adapted by the user to suit their own production needs.