Introduction to BOMapp API |

This manual is intended for those who wish to make use of BomAPI. It is expected that you have some programming experience.

To ensure the production process, the engineer must provide not only graphic information in the form of drawings but also different specifications. These include information about parts, workpieces, overall need of materials, etc. Information about wooden products is presented in a specific manner. One of the most important functions of our CAD systems is automated generation of reports providing all information about the designed product required for manufacturing. The BOMapp copies this information from the model, processes it flexibly and provides it in the form acceptable within the organization. This function is performed by the BOM (Bill of Material) command. The report generator provides its information in the text file format (.xls, .xslx, .ods, .xml, .txt and others). These templates can be used as prototypes and give an idea what the user can extract from BOM. Users can modify these templates at their own discretion, adapting them to individual business needs. Additionally, it is a good example of how data can be stored, organized and accessed using various keywords (in a template), and output methods (using templates or a provided API).

These templates can be used as prototypes and give an idea what the user can extract from BOM. Users can modify these templates at their own discretion, adapting them to individual business needs. Additionally, it is a good example of how data can be stored, organized and accessed using various keywords (in a template), and output methods (using templates or a provided API).

To ensure the functioning of the generator, you must have Spreadsheet or text editor installed on your computer. The BOM generator allows you to flexibly organize the data exported in different forms which are defined in the templates. Our templates are provided as MS Excel files containing keywords based on which the final report tables are created. The user can easily modify these templates and adapt the information being generated to his individual needs.

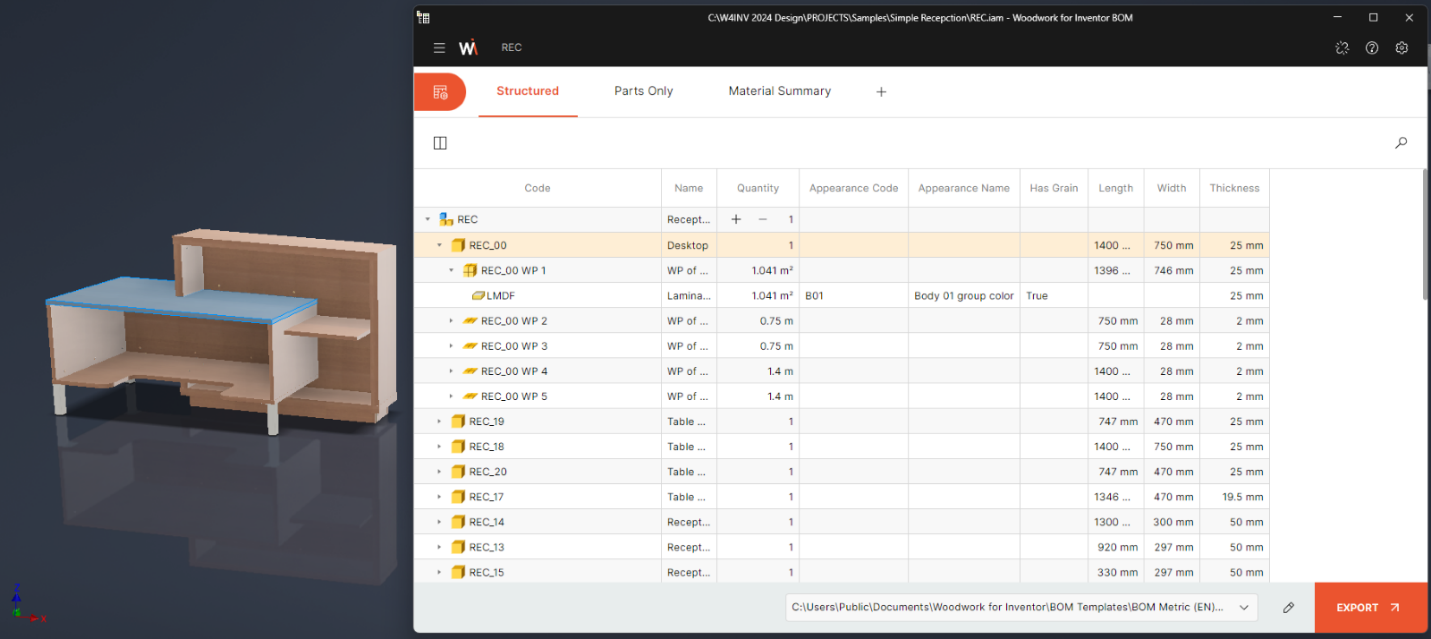

Here are a few examples of provided templates:

BOM Metric (EN).xlsx - BOM template in metric units (in English).

BOM Imperial (EN).xlsx - BOM template in imperial units (in English).

The following sheets are provided in these templates:

Product Structure - product structure BOM

Composite Parts List - BOM of composite parts with expanded internal structure

Multilayer Parts List - BOM of multilayer board parts

Complete Parts List - complete list of all material part types

Cutting Parts List - list of cutting parts

Material Summary - summary of materials

Structured Material Summary – structured list of used material groups, materials, and final parts

Material Sum by Products - material summaries by products within the assembly

Rename Configuration - rename configuration provides a list of materials stating which material names come from the CAD systems’ database. If we speak about Purchased components, the names read from the Properties (metadata) component have been changed to different names during replacement configuration.

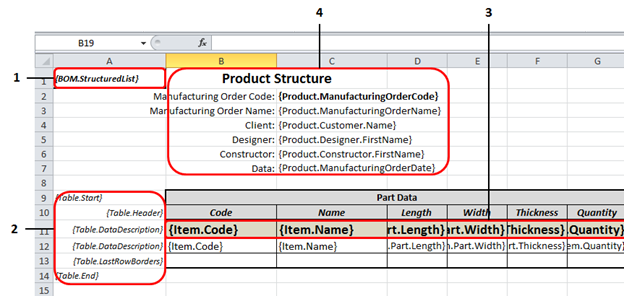

As mentioned previously, the BOMapp template ca be expressed as an MS Excel file. When defining a template, you need to observe the following rules:

You may create a different type of BOM in each file sheet.

A single sheet can only contain one type of BOM.

A sheet can contain a definition of several tables. Each table has its own unique way of presenting information typical of this type of BOM.

Keywords that are contained in all fields and that describe the BOM form need to be placed in curly brackets "{ }". The BOMapp interpreter understands it as a sign that a keyword operand needs to be searched within the brackets.

The A column of the template is intended for the descriptive BOM section:

BOM type is entered in the A1 cell. The BOM can be of the following types:

BOM.StructuredList: BOM containing hierarchically structured information.

BOM.PartsList: BOM containing only lists of product parts.

BOM.ItemsList- a specification, where all model data items are presented just like in plain BOM.

BOM.MaterialSummary: BOM containing different forms of material summaries of the assembly.

BOM.MaterialsSummaryByProduct: BOM containing a material summary for the first-level assembly products.

BOM.StructuredMaterialsSummary: Extracts and displays structured list of used materials, their quantities and which parts have assigned specific material.

Information describing the table is entered in the A column. BOM.StructuredList specifications can only contain one table. Other BOM types can contain several table template descriptions per single template sheet. Table template description consists of several rows describing the following aspects of table creation:

Table.Start [table type]: indicates the start row of the table. If a table type is not specified, it means that this BOM type will start from the general table without classifying items depending on their material. If a table type is specified, it will present information depending on the material type defining the table. For example, in BOM.PartList specifications, Table.Start.Board keyword means the start of the part table containing a part list which includes board material.

Table.Header: indicates row(s) in which table header data can be placed..

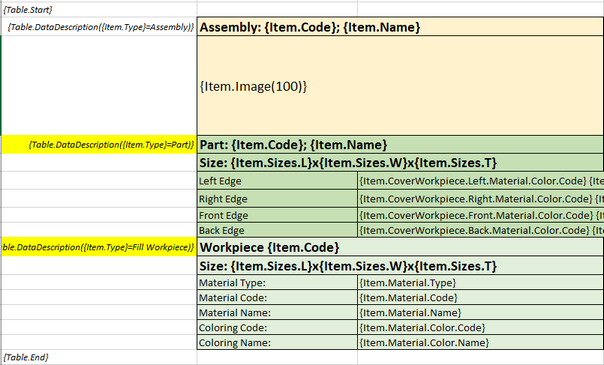

Table.DataDescription: indicates rows containing item attributes defining information that needs to be exported to the table column. In BOM.StructuredList specifications, row description can be the same as with a differently formatted Table.DataDescription row. BOM generator interpreter understands this as a description intended to each time format data at the next level of the model hierarchy. The first row is used for the top level, the next row is used for the second level, etc. This allows the user to create clear and easy-to-read BOM forms.

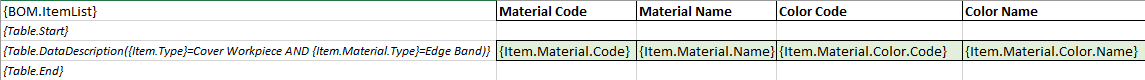

Data Filter- optional parameter. The user can create a filter, which will allow exporting only the data that meets the <Data Filter> criteria as the BOM generator iterates through the model data tree. Filter creation principles are as follows:

({keyword1}=checked_value1 AND {keyword 2}=checked_value2....)

In order to have only exported Edge Band workpieces displayed in the {BOM.ItemList} specification, the following BOM form can be provided:

{Table.DataDescription} describing keywords can be arranged on a MS Excel worksheet until the next {Table.DataDescription} keyword or the table end keyword {Table.End}. In other words, the data of the Item can be exported to more than one row in MS Excel.

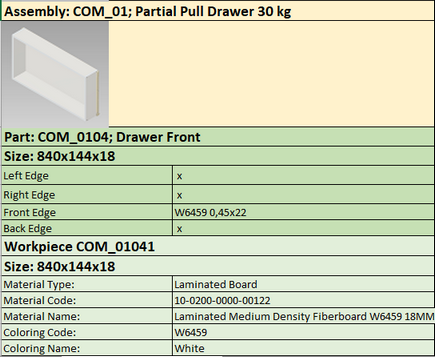

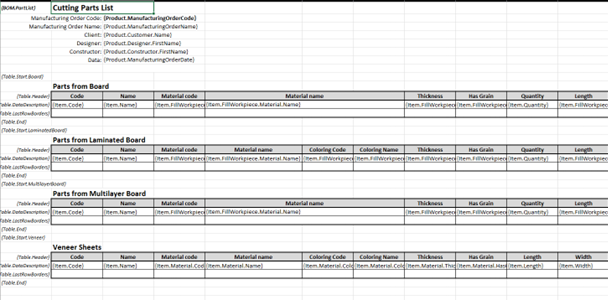

BOM template example

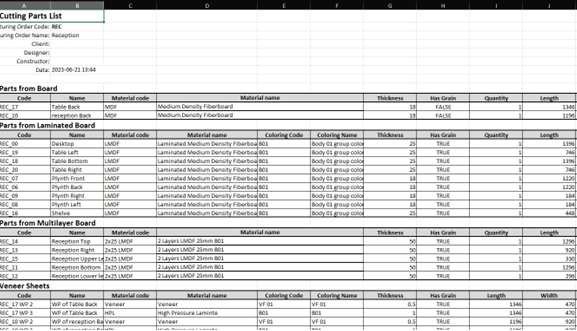

BOMapp generated result

BOM template example

BOMapp generated result

Table.LastRowBorders: here you can define the formatting of the last row which may differ from that of the regular table row.

Table.End: end of the table description.

In this row, keywords of the exported data are entered in desired order. The program iterates through the model data depending on these keywords and exports the appropriate data values requested by the keyword.

The header of the entire BOM which is formed from the data provided when entering header data. To read more, click here .

When forming the final BOM based on the template, BOMapp removes the A column and exports the information starting from the A1 cell.

When interpreting the template data and generating the final BOM, BOMapp also copies the template cell format. This allows enhanced the readability of the generated BOM.

A list of keywords used to define BOM fields is presented here .

Note

NoteImportant: When generating MS Excel file, BOM generator additionally analyses the generated rows in MS Excel worksheet and their uniformity. If the lines are the same, they are included as a single row and the quantity of the component being defined is increased. This can be important when working with purchased components. For example, you have two different Autodesk Inventor components with the same Part Number and Description. If their data rows are the same, they will be included as a single item in MS Excel specification. However, if you ask to export Customer iProperty that can be different for the above components in BOM template, these components will be presented in different rows.

A BOMapp API serves as a tool for gaining access to information associated with a product's additives, substances, and specs. This API allows developers to seamlessly retrieve BOM records from a document and store it in diverse formats, inclusive of text files, databases, or another favored destination. The flexibility provided through this API lets users successfully manner the retrieved statistics and save it in an appropriate layout for unique software/business demands.

Whether it involves storing the records in a local document system, persisting it in a database for future usage, or moving it to a remote server, the BOMapp API empowers developers to seamlessly integrate report records retrieval and storage functionalities. By leveraging the BOMapp API, developers can make efficient handling and utilization of records within their packages, enabling streamlined methods and advanced productivity.

So, this allows third-party applications to integrate with BOMapp. Through an API, components for PDM, ERP and other systems can communicate and transfer data form BOMapp to another environment.

BOMapp operates using .NET environment and tools, so users shall prepare their workplaces accordingly, load our prepared example and execute necessary commands.